In the realm of electronic machines, precise and controlled movements are paramount for optimal performance. This is where stepper motors play a transformative role. Steppers, with their ability to convert digital signals into precise rotational movements, have become the go-to choice for applications that require accuracy, repeatability, and versatility

Whether you are looking forward to buying steel products, or require precision work, stepper motors can change the way industries operate. Here are the multiple benefits of using stepper motors in the electronic industry.

Unparalleled Precision And Control

Stepper motors excel in providing unparalleled precision and control, making them indispensable in electronic machines. These motors move in discrete steps, responding to digital commands with remarkable accuracy. Whether it’s positioning a printer head, controlling robotic arms, or guiding the movements of CNC machines, steppers enable exacting control over motion.

With their ability to maintain precise positioning without the need for feedback mechanisms, steppers offer an inherent advantage in applications where accuracy is paramount. This precise control enables enhanced quality, reduced errors, and improved overall performance in a wide range of electronic machines.

Versatility And Adaptability

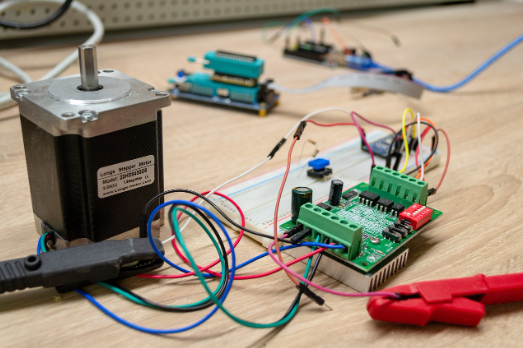

Stepper motors are renowned for their versatility and adaptability to various applications. They are available in different sizes, torque ratings, and step resolutions, allowing for customization to meet specific requirements. With the availability of a wide range of spare parts, like Ultratech Titan, stepper motors are becoming more favorable for industries. Steppers can be found in diverse electronic machines, including 3D printers, CNC machines, robotic systems, medical equipment, and automated production lines.

Their ability to provide precise and repeatable movements in a controlled manner makes them indispensable across industries. Furthermore, stepper motors can operate in open-loop systems, simplifying the control architecture and reducing costs. This versatility, combined with their robust design and reliability, has made steppers a favored choice for countless electronic machine applications.

Efficiency And Energy Conservation

Stepper motors exhibit excellent energy efficiency, which is a critical consideration in electronic machines. Unlike other types of motors, steppers draw power only when they are in motion, resulting in energy savings during idle periods. Moreover, steppers maintain their position without requiring continuous power, further contributing to energy conservation. This efficiency is particularly valuable in battery-powered devices and applications where power consumption is a concern.

Additionally, steppers generate minimal heat, reducing the need for elaborate cooling mechanisms. The combination of energy efficiency and reduced heat dissipation enhances the reliability and lifespan of electronic machines, leading to cost savings and environmental benefits.

Future Advancements And Innovations

As technology continues to advance, so does the potential of stepper motors in electronic machines. Ongoing developments in motor design, materials, and control algorithms are pushing the boundaries of stepper performance. Improved torque density, higher step resolutions, and enhanced positional accuracy are being achieved, enabling even more precise movements.

Integration with advanced control systems and communication protocols, such as Fieldbus and industrial Ethernet, further expands the capabilities and connectivity of steppers. Additionally, research is exploring the incorporation of smart features like self-diagnosis and predictive maintenance, ensuring optimal performance and reducing downtime. With continuous innovation, steppers are poised to play an increasingly vital role in driving the evolution of electronic machines.